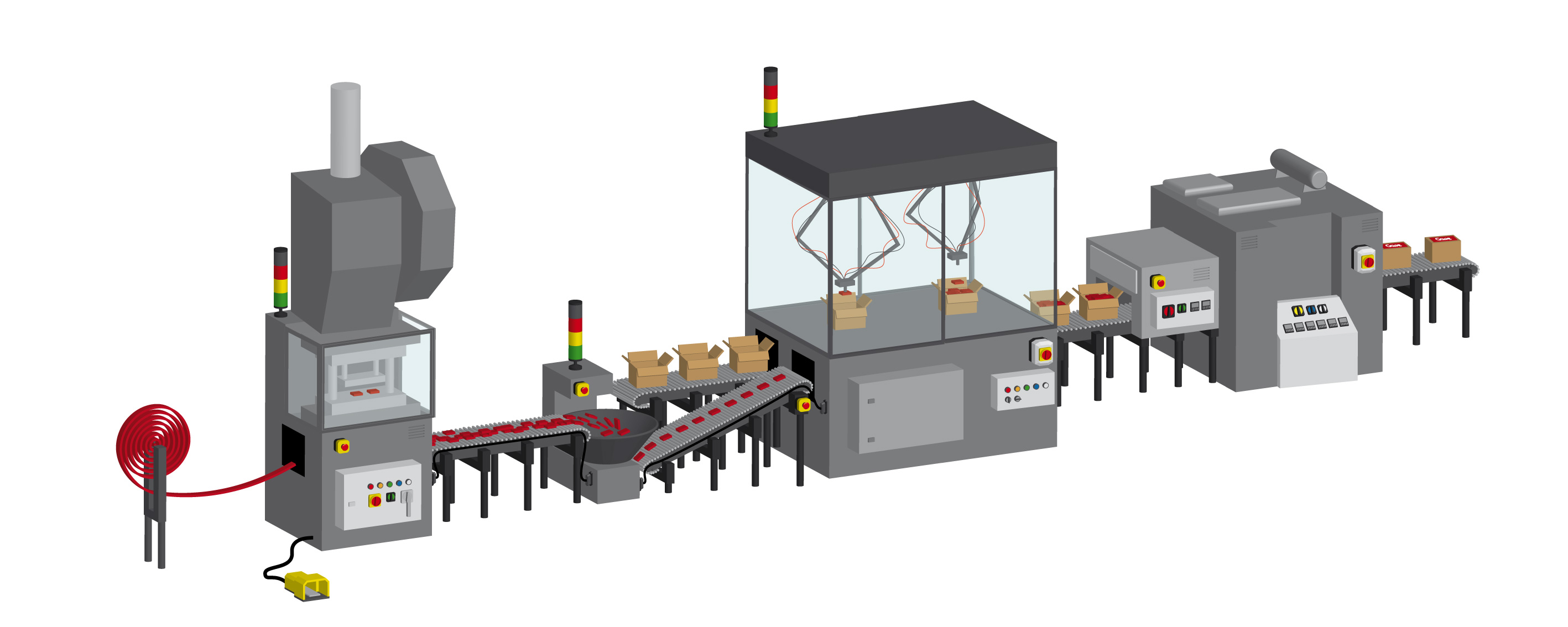

At Gave, we understand the demands of the machinery manufacturing (OEM) sector, where safety and reliability are essential, as well as the need to improve production efficiency by optimizing processes and minimizing downtime.

Human-machine interaction

Effective interaction between the operator and the machine operating system in industry is essential for optimizing production tasks. Clear communication between equipment components and the user brings key benefits in terms of efficiency, safety, and competitiveness for companies.

Predictive maintenance and fault prevention

Information obtained from an illuminated switch, a monitoring relay, or a simple pushbutton can help predict faults in advance and prevent a production line shutdown, avoiding the costs associated with emergency interventions and unexpected repairs.

Greater safety and sustainability in industrial environments

An advanced communication system between humans and machines allows companies to better adapt to technological advances, optimize operations, and ensure a safer and more sustainable working environment.

Control and signalling devices

Innovative solutions such as illuminated switches transform design by integrating control and signaling in a single element, making operator tasks more efficient.

Intuitive indications

Colour coding provides quick understanding by the operator, allowing for a clear interpretation of the situation and facilitating decision-making. This is especially important in industrial settings where conditions can change rapidly, requiring quick and precise decisions.

Additional signalling

There is a type of signalling associated with a discrepancy between the instruction and the actual status of the process. This may indicate, for example, the end of a process cycle, where an operator's action is required (e.g., refilling a material magazine).

The range of illuminated switches with signalling capabilities addresses these needs in production processes, incorporating additional features such as blinking light, an audible warning buzzer, or blinking and buzzer combined.

Electrical panel monitoring and protection

We can ensure optimal panel operation using various power monitoring and management elements. The use of surge arresters protects the many electronic devices characteristic of automation systems.

The high presence of electronic components in modern machinery has made protecting these elements a priority, with surge protection becoming indispensable.

Automatic production processes are characterized by the use of timers. Electronic reliability and precision are key to ensuring efficiently operating automated system.

Maintenance operation safety

Maintenance operations can be carried out safely by properly isolating the areas where maintenance work is required.

The use of LD bypass changeovers allows maintenance work to be performed without stopping production. This application is especially useful when working with variable frequency drives.

Enclosed switch disconnectors allow a circuit to be electrically isolated in emergency or maintenance situations manually, and therefore must be installed at the machine level.

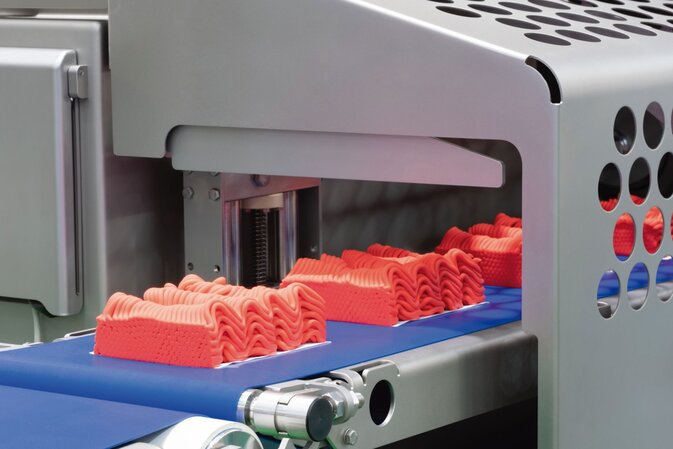

IP69K handles keep safety and hygiene requirements in environments exposed to acidic corrosive elements in the air and solvents during cleaning operations. It also must be considered the exposure to accidental shocks that risk producing bites on the enclosure surface.

In short, the IP69K certification is the highest degree of protection that exists. For that reason, the new range of IP69K handles is most suitable for a wide variety of hostile environments exposed to harsh safety and cleaning conditions.

CATALOGUES

RELATED PRODUCTS

VIDEOS

Handles IP69K - A solution for heavy-duty cleansing environments

Handles with antimicrobial technology